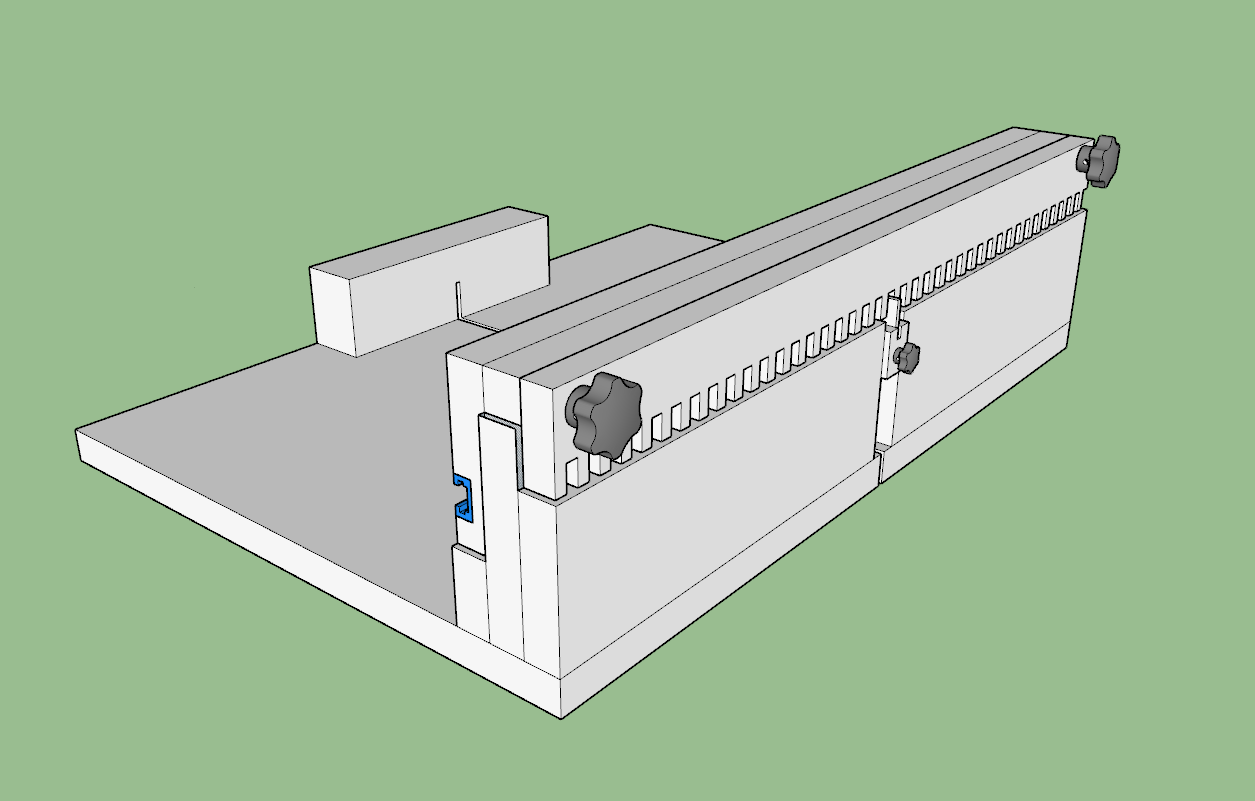

Image 1 of 9

Image 1 of 9

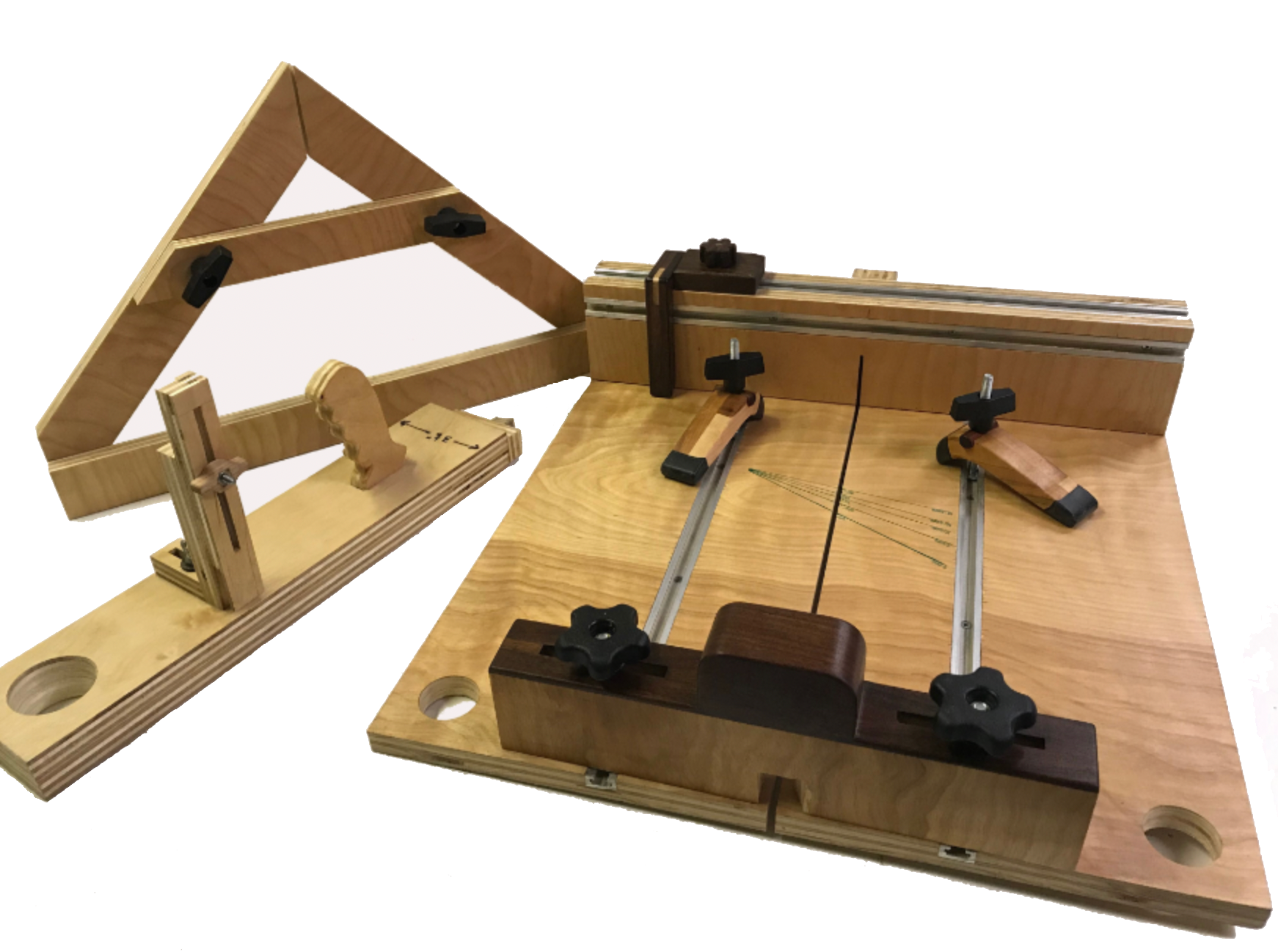

Image 2 of 9

Image 2 of 9

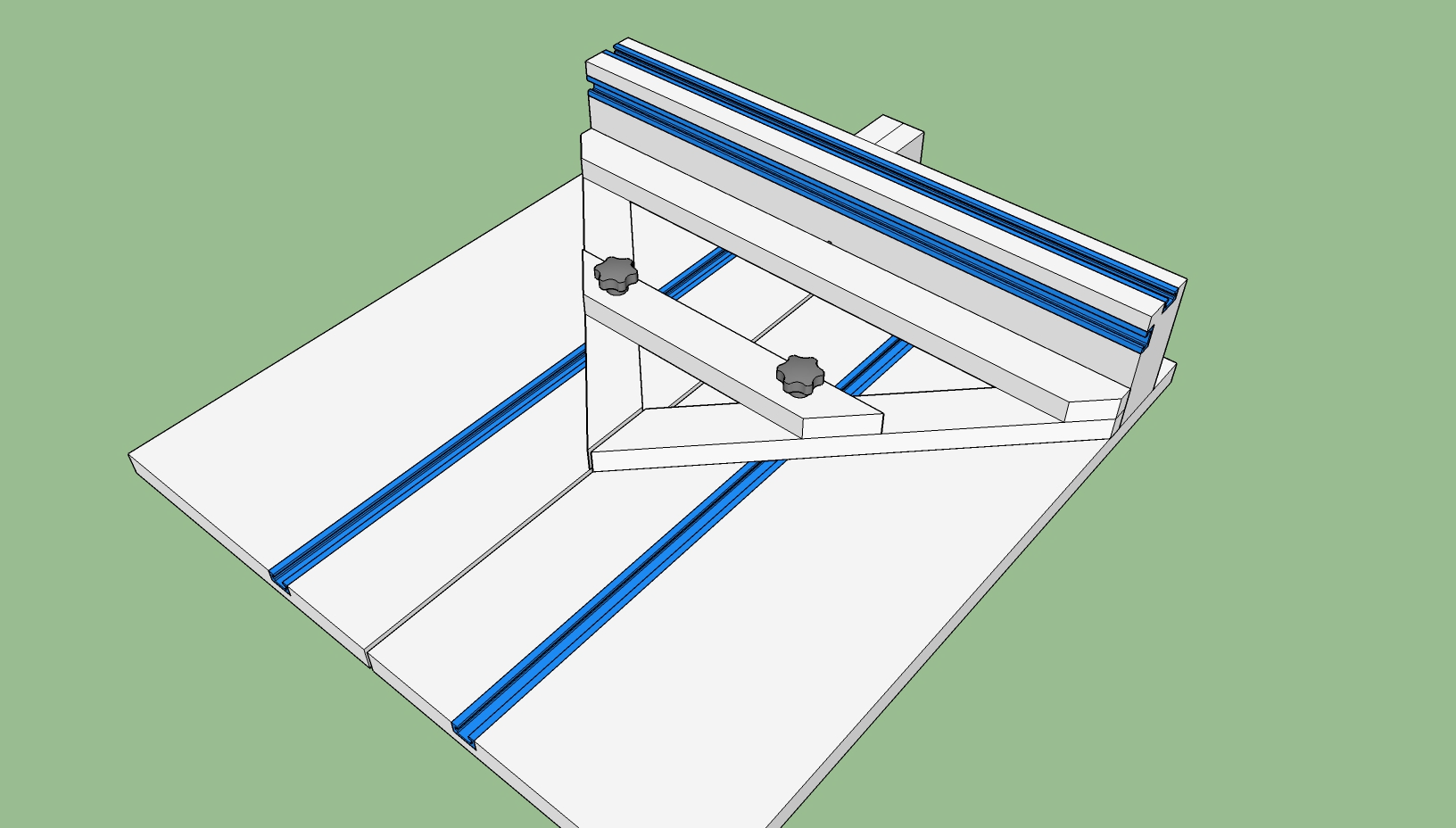

Image 3 of 9

Image 3 of 9

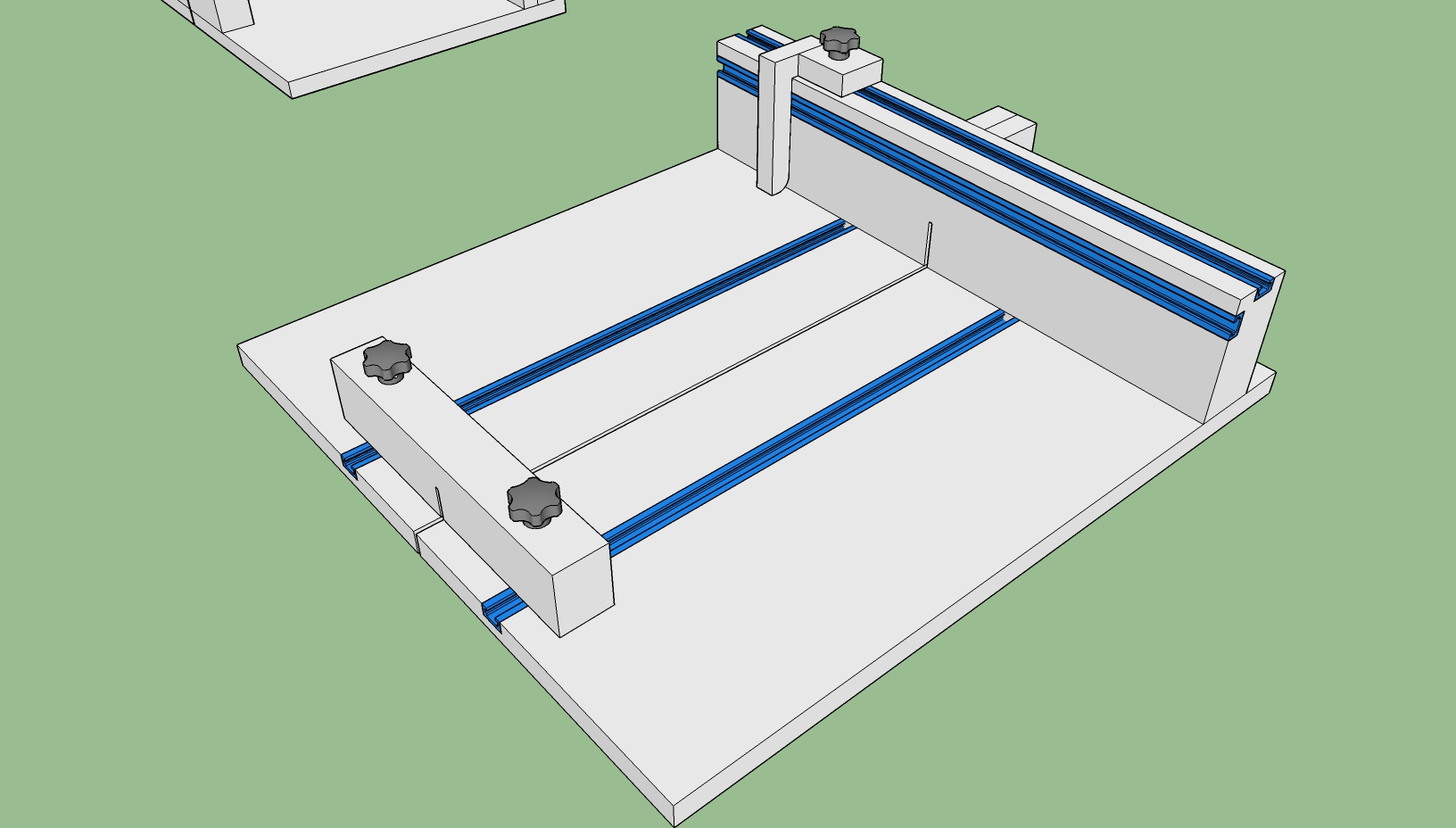

Image 4 of 9

Image 4 of 9

Image 5 of 9

Image 5 of 9

Image 6 of 9

Image 6 of 9

Image 7 of 9

Image 7 of 9

Image 8 of 9

Image 8 of 9

Image 9 of 9

Image 9 of 9

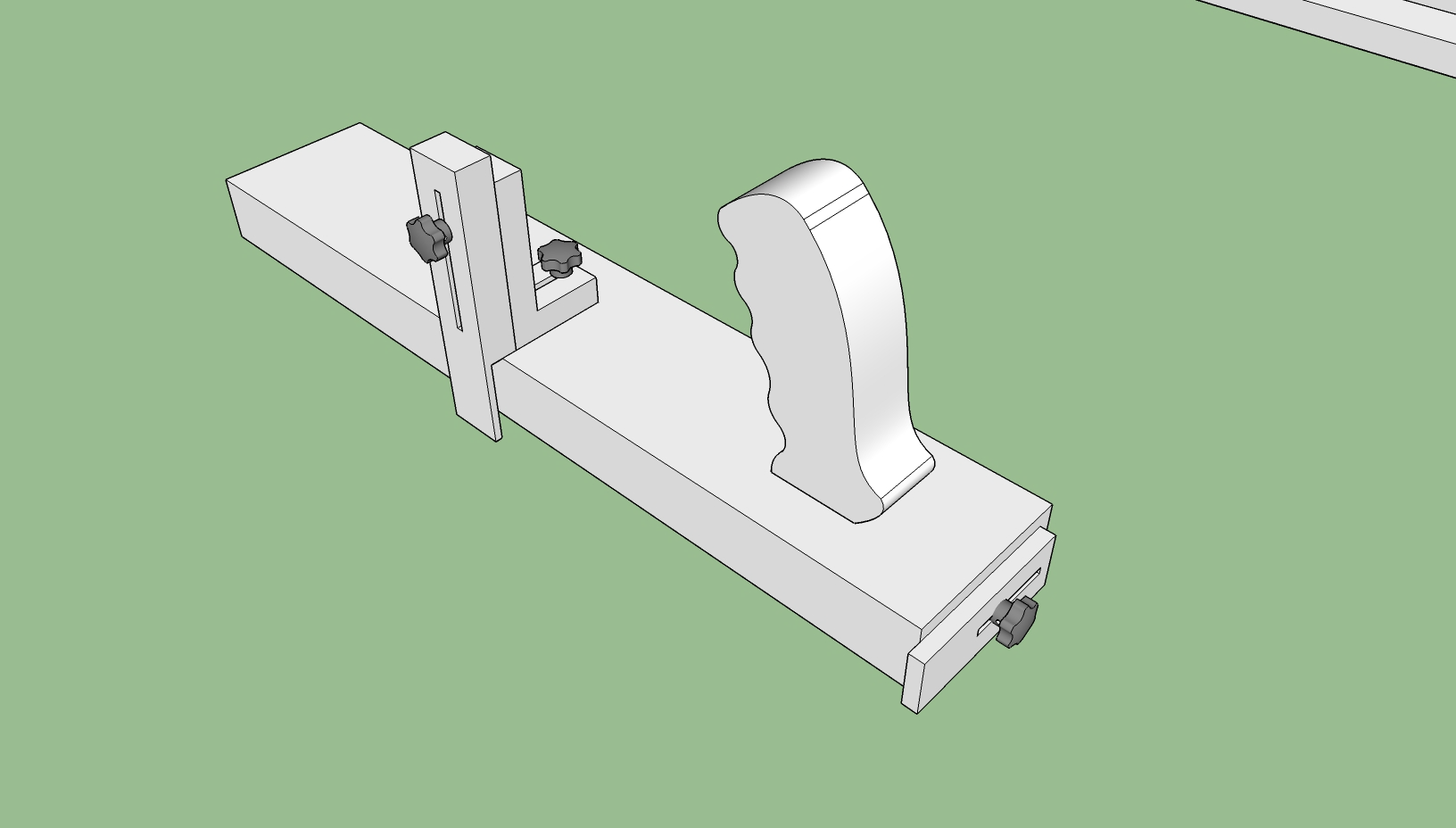

Fisher's CNC Lathe

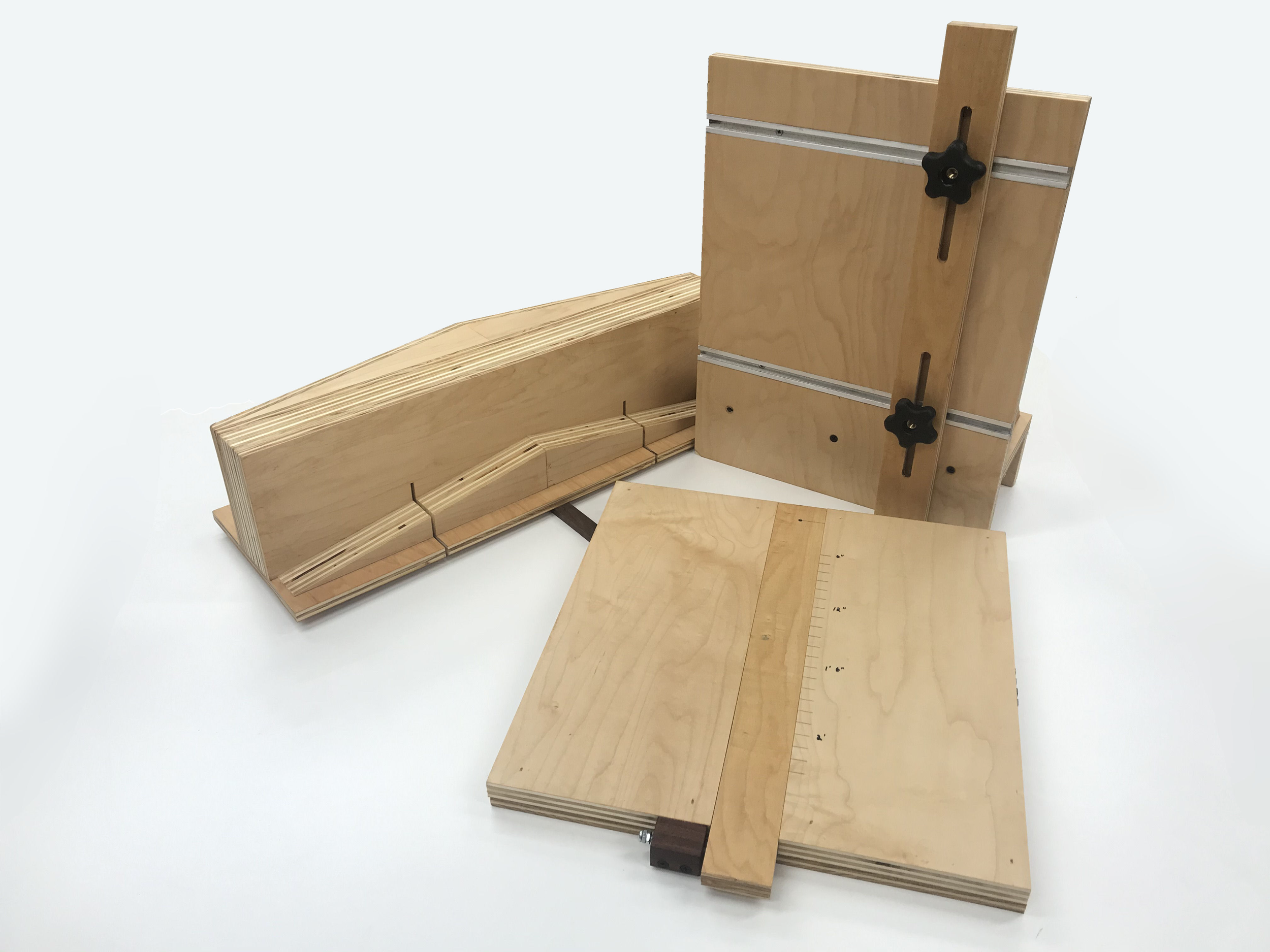

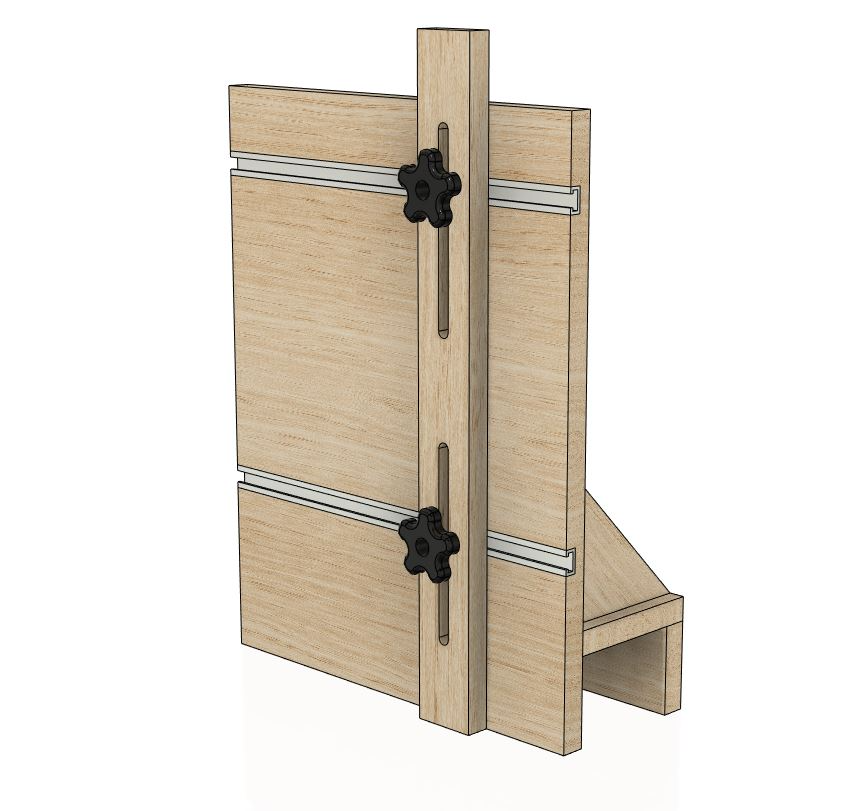

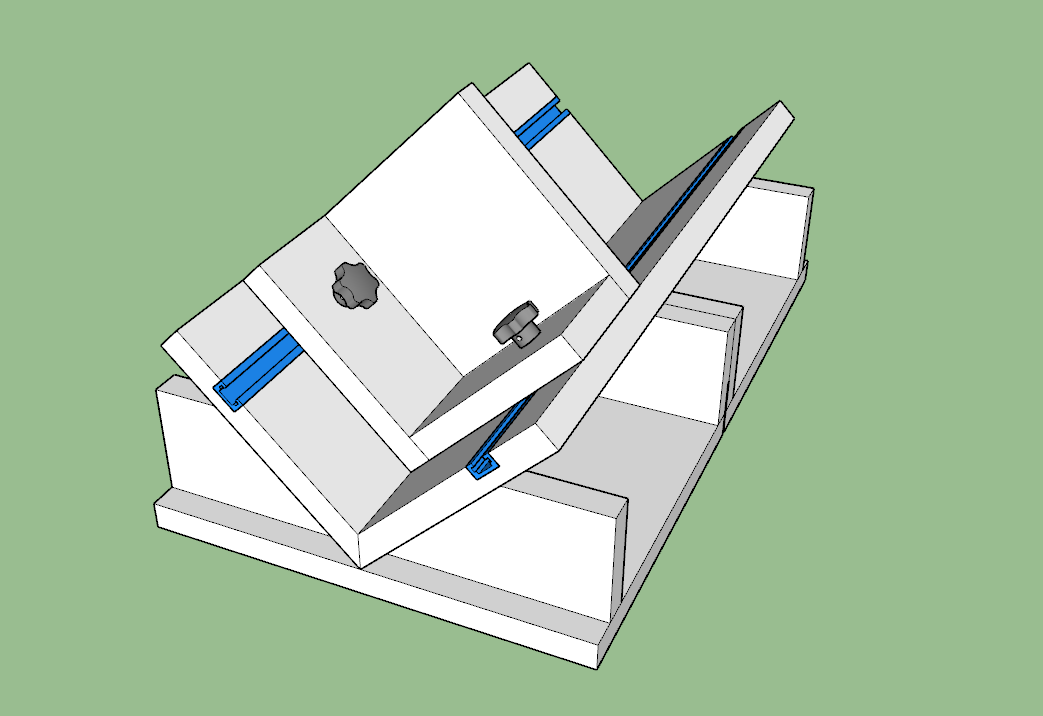

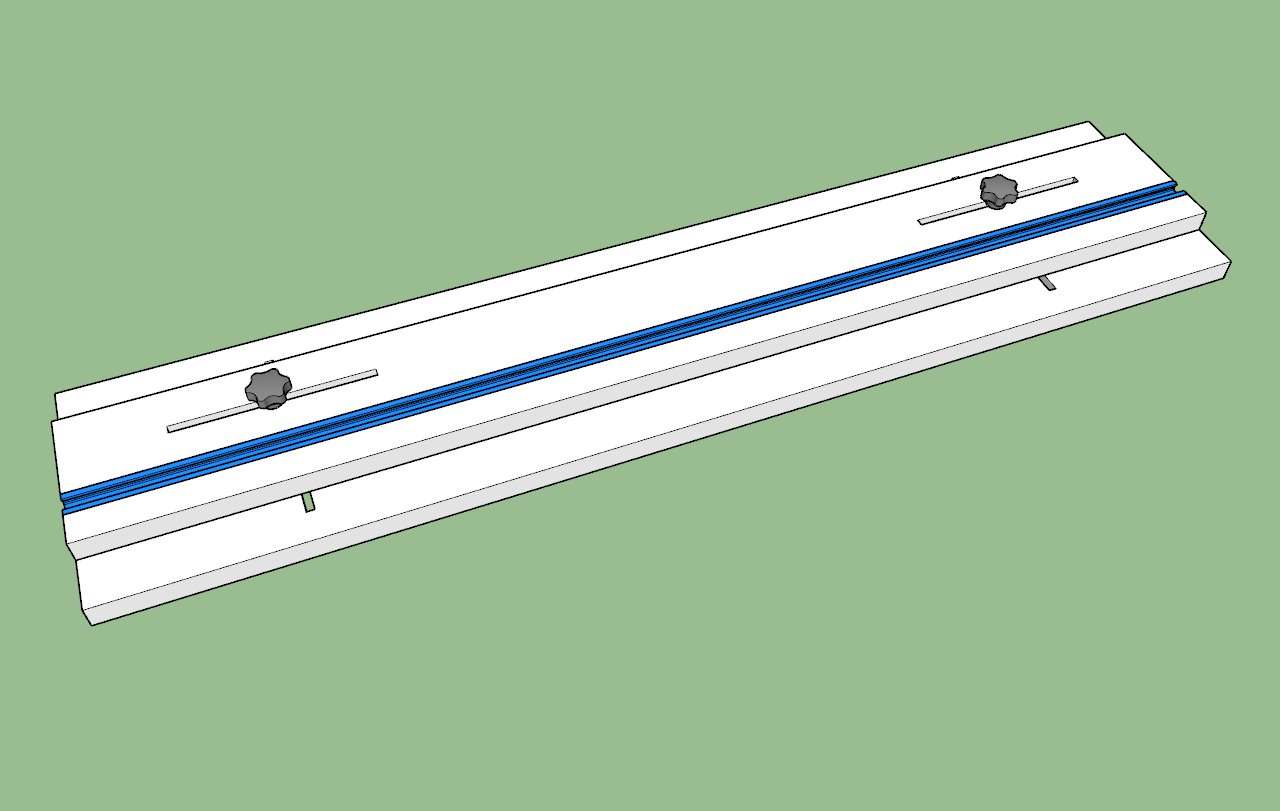

I don't have a lathe in my shop and, on occasion, I've needed to create some round pieces. Up until now, I've had to utilize my belt sander to make some imperfect shaped pieces for my projects. What I really needed was a way to consistently and perfectly create a round shape. And since there's nothing more consistent than a CNC, I designed and built a lathe that works with the machine! This is an easy-to-build shop jig made from 3/4” plywood, simple hardware, and utilizes your drill to spin the stock. With this CNC lathe, I can now easily make absolutely identical little spindles and pieces on the CNC.

This lathe is designed to work on just about any CNC machine provided that your CNC work area is at least 31 inches on the X axis, more than 11 1/2” on the Y, and has more than 3 1/4” in height on the Z axis.

These plans include step-by-step instructions, a DXF and/or SVG file(s) to import into your CAM software, the Fusion360 project file, and the post-processed Gcode specific for OneFinity CNC machines.

These instructions and files are used to build the Fisher's CNC Lathe that is depicted in the video on Fisher's Shop YouTube channel. Haven't seen the video? Here’s a link to it!

**Please note these are DIGITAL FILES, not the physical item shown as the example.

I don't have a lathe in my shop and, on occasion, I've needed to create some round pieces. Up until now, I've had to utilize my belt sander to make some imperfect shaped pieces for my projects. What I really needed was a way to consistently and perfectly create a round shape. And since there's nothing more consistent than a CNC, I designed and built a lathe that works with the machine! This is an easy-to-build shop jig made from 3/4” plywood, simple hardware, and utilizes your drill to spin the stock. With this CNC lathe, I can now easily make absolutely identical little spindles and pieces on the CNC.

This lathe is designed to work on just about any CNC machine provided that your CNC work area is at least 31 inches on the X axis, more than 11 1/2” on the Y, and has more than 3 1/4” in height on the Z axis.

These plans include step-by-step instructions, a DXF and/or SVG file(s) to import into your CAM software, the Fusion360 project file, and the post-processed Gcode specific for OneFinity CNC machines.

These instructions and files are used to build the Fisher's CNC Lathe that is depicted in the video on Fisher's Shop YouTube channel. Haven't seen the video? Here’s a link to it!

**Please note these are DIGITAL FILES, not the physical item shown as the example.